Airbus: Catia Viewer

How does someone start building an airplane?

Intense training is needed to teach how to create a complex and at the same time one of the safest means of transport in existence.

After decades of expensive physical training, the most innovative technologies are helping to build the aircraft of the future at a lower cost while maintaining quality and reliability.

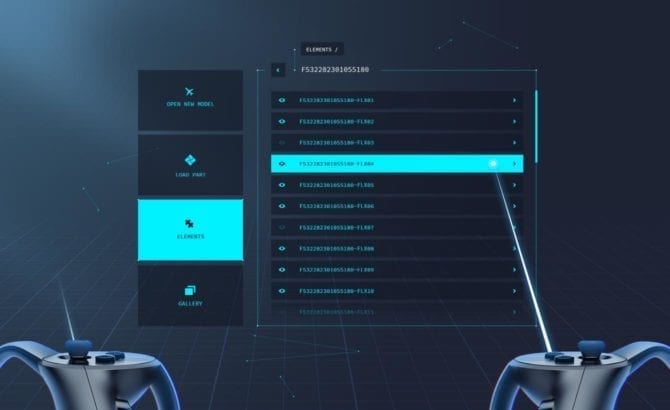

The Catia Viewer developed by Plain Concepts for Airbus presents a new way to view 3D models by using today’s virtual reality and Evergine technologies.

This virtual reality-based application for the Oculus Rift device can simulate one or several work environments on a given task, and allows for very natural manipulation based on the controls.

Training new workers in the aerospace industry is tedious, as the slightest assembly failure can lead to great risk. For this reason, Airbus has always operated with workbenches, although few because they are expensive and suffer from continuous wear and tear. In addition, a trainer for each new worker limits the number of new recruits.

The process

The operator has virtual hands that allow him to both disassemble a part and adapt the size of the workspace to visualize the details of real aircraft parts.

Results

- Thanks to the development and use of virtual reality, this project reduces the cost of producing the parts of an airplane or heavy machinery, avoiding multiple prints through virtual simulation of the parts before they are physically prototyped.

- It eliminates the physical wear and tear that used to occur on real parts and reduces the cost and space required to have more working scenarios in the same manufacturing plant.

- In addition, it allows a trainer to be in another location or to be completely virtual scoring the work done on the test bench by the trainee worker.

- Plain Concepts also developed a loader that could import models from CATIA and SolidWorks, based on the STP and IGUES format. These formats are vectorial and define parts with infinite precision, so a system was developed to adapt the resolution in triangles of each part according to the distance at which they are located, to display at an appropriate frame rate in virtual reality glasses.

We are ready for new challenges