Manuel Caballero

Plain Concepts Research

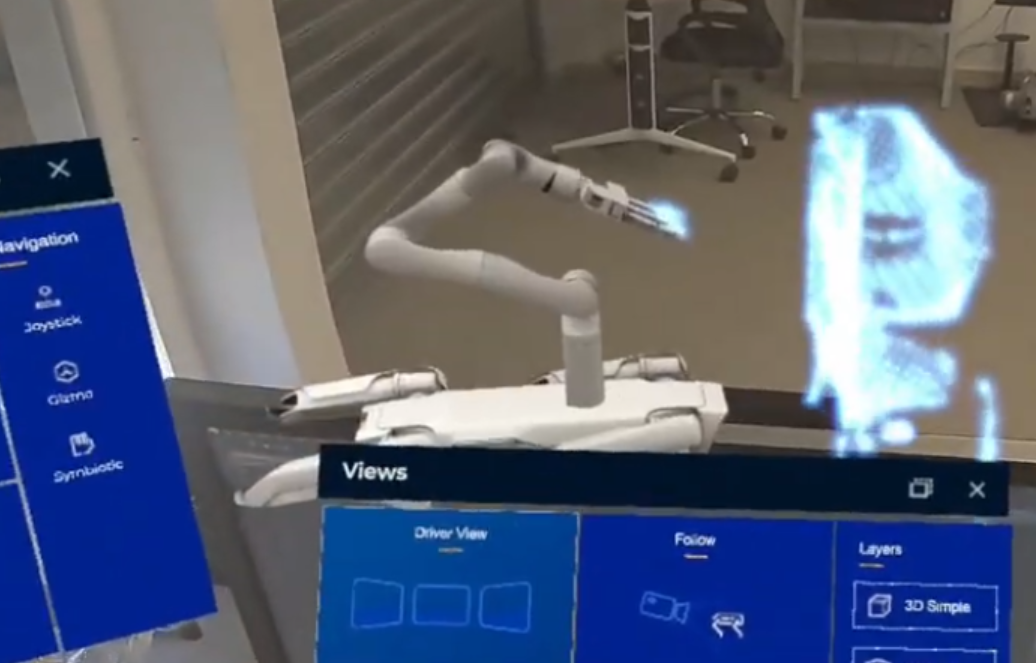

In our previous article about the MRLink platform, we introduced our innovative approach to robot teleoperation in virtual reality. This solution opened the door to intuitive, immersive, and precise control of remote robots, allowing users to interact with their environment as if they were physically present.

Since that milestone, we’ve been working on further enhancements to the platform, focusing on richer sensory input and improving situational awareness for operators. Today, we’re excited to share some of the new features designed to deliver more data, better context, and a more natural teleoperation experience.

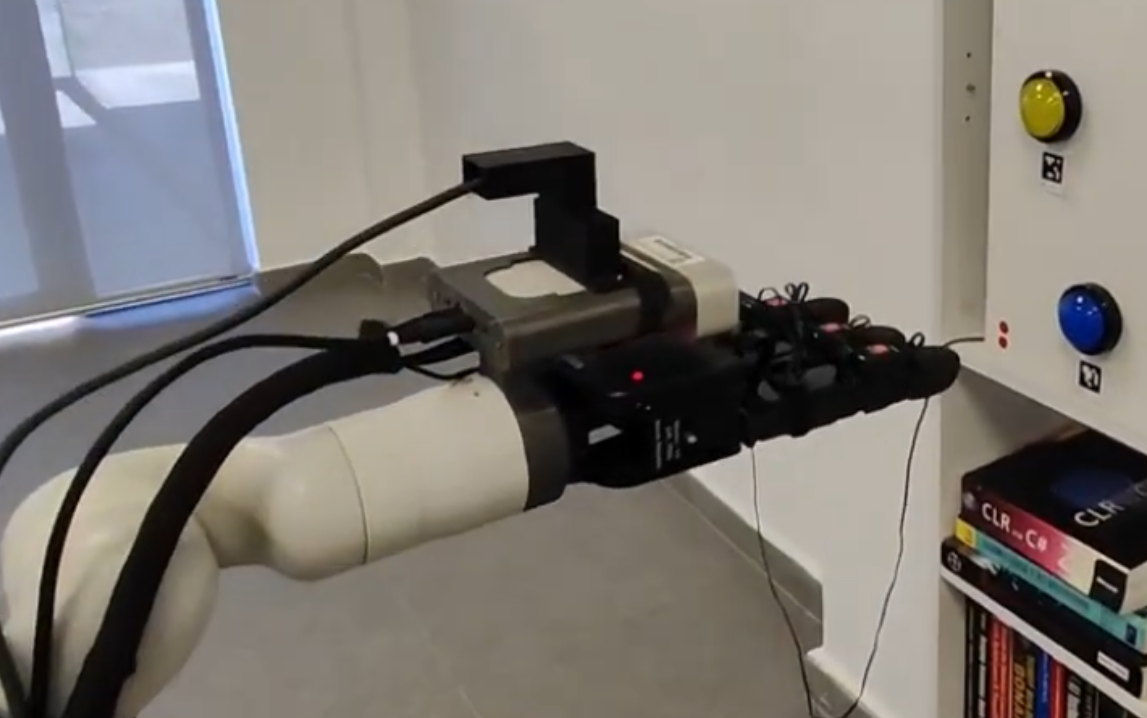

One of the most significant upgrades to the system is the integration of the Azure Kinect. This device serves both as a remote camera and as a depth sensor, enabling us to capture point cloud data in real time.

By visualizing this data directly inside the VR application, operators can see and understand the spatial layout of the remote environment with unprecedented clarity. This enhances depth perception, improves navigation, and supports more accurate manipulation tasks, especially in complex or cluttered spaces.

Beyond navigation, depth sensing opens a wide range of applications in industrial maintenance:

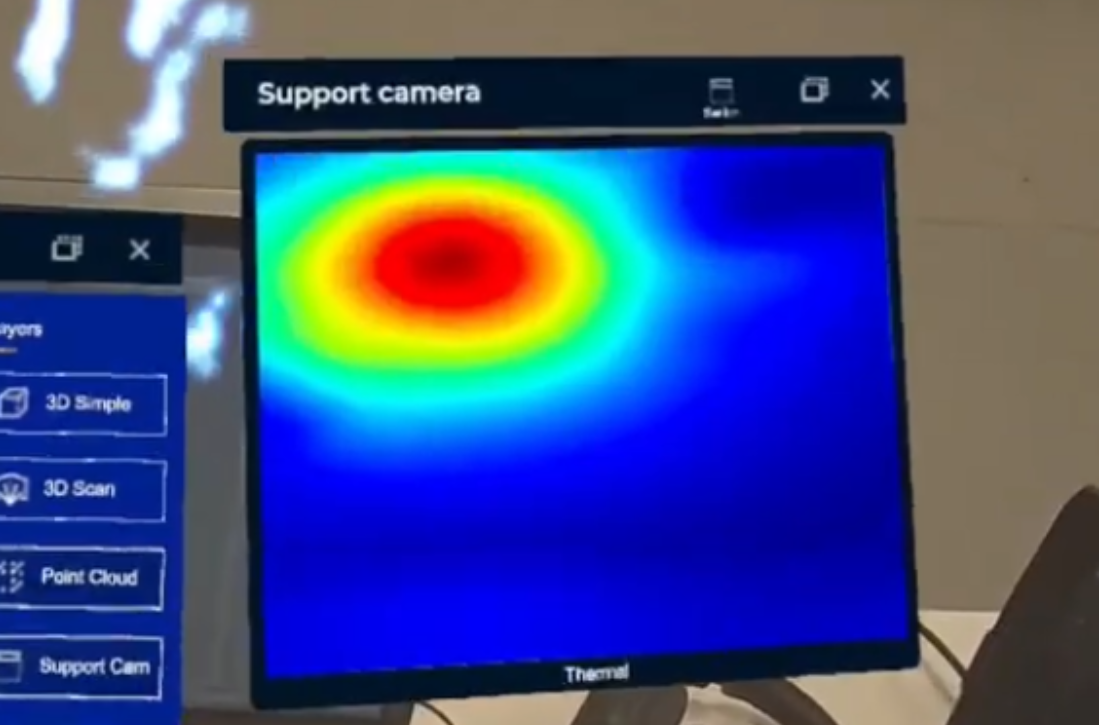

Another powerful addition is the inclusion of a thermal camera. This feature allows the system to detect temperature anomalies in equipment, giving operators critical information about the state of machinery before they even touch it.

For example, identifying overheated components can help prioritize repairs, assess potential risks, or plan maintenance procedures more efficiently. This layer of thermal feedback enhances decision-making and safety during remote interventions.

In practical terms, thermal data can support multiple industrial use cases:

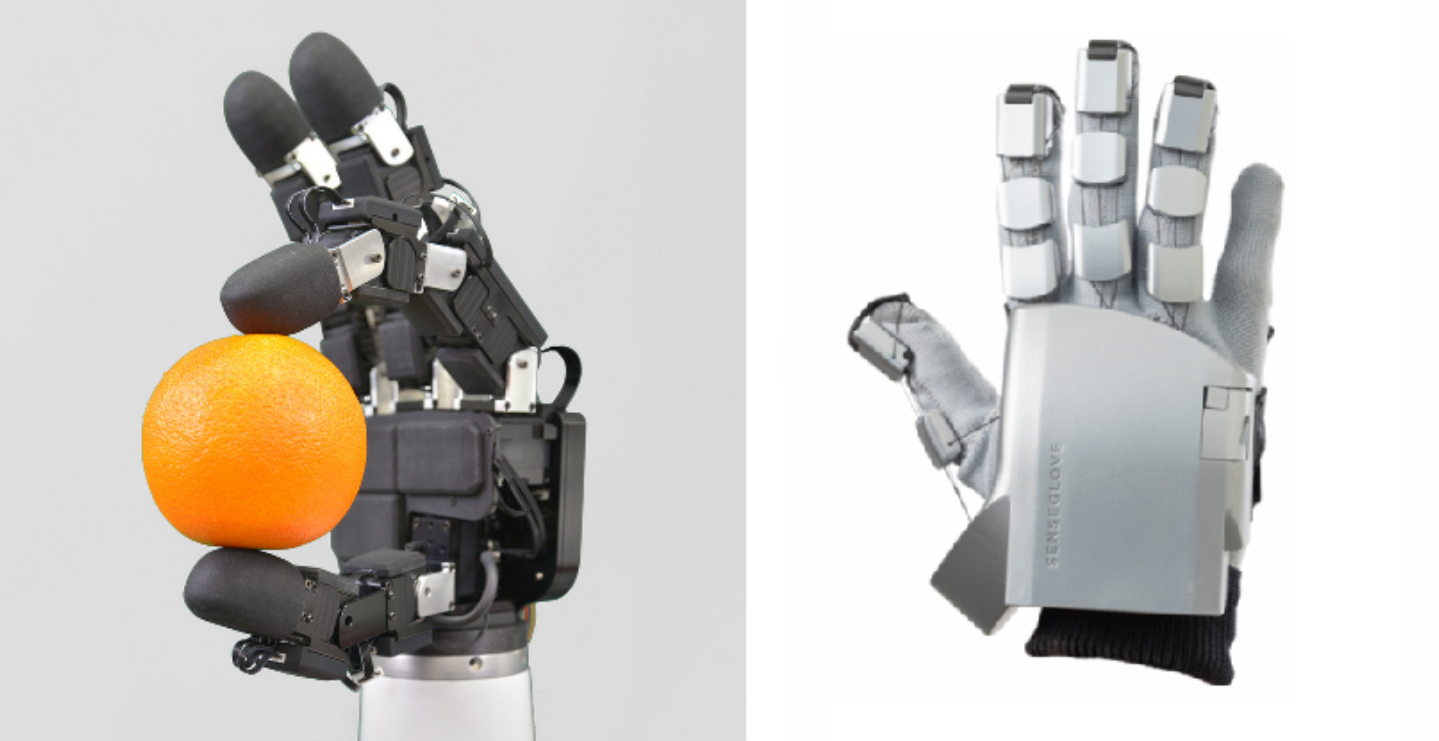

While data visualization is important, touch remains a key element of how humans interact with the world. That’s why our next step involves integrating XELA Robotics tactile sensors and the SenseGlove Nova 1 gloves.

This combination will enable operators to feel interaction with remote objects, such as gripping a tool, pressing a surface, or manipulating delicate components. This tactile feedback will further bridge the gap between physical and virtual presence, making teleoperation more intuitive and precise.

Aside from grip force feedback, other practical applications of tactile sensing in industrial maintenance include:

The main application we are pursuing with this type of teleoperation technology is in the highly controlled industrial environment that is a particle accelerator facility, dedicated to fusion technology research. These sites operate with complex, delicate, and sometimes hazardous systems where direct human access is limited or requires extensive safety procedures.

By combining remotely controlled robots with depth sensing, thermal imaging, and tactile interaction, operators can perform inspections and maintenance tasks safely inside restricted zones without interrupting critical experiments or exposing personnel to radiation, high magnetic fields, extreme temperatures, or dangerous noise levels.

This integration of advanced sensory feedback with teleoperation represents a major step forward in these environments, where operational uptime, precision, and safety are essential. It transforms maintenance into a controlled, data-rich, and proactive process, accelerating both research and technological development.

The evolution of MRLink continues to push the limits of immersive teleoperation. With the integration of depth sensing, thermal imaging, and tactile feedback capabilities, operators will benefit from a richer, more complete understanding of remote environments.

These enhancements mark a step toward making remote robotics not only more capable but also more human-centric. We’re excited to keep innovating, expanding the platform, and bringing new possibilities to industries that rely on safe, efficient, and intelligent remote operations.

This work has been developed in the framework of NEURON-DONES project (Industrial research in critical technologies for the operation and maintenance of large scientific facilities applied to IFMIF-DONES to advance on the path to fusion.

This project, file MIG-20221067, has received funding from CDTI – Centro de Desarrollo Tecnológico y la Innovación – through the call for applications for the ‘Misiones CDTI’ Program 2022 and from the Next Generation Program of the European Union and Recovery, Transformation and Resilience Plan.

Manuel Caballero

Plain Concepts Research

| Cookie | Duration | Description |

|---|---|---|

| __cfduid | 1 year | The cookie is used by cdn services like CloudFare to identify individual clients behind a shared IP address and apply security settings on a per-client basis. It does not correspond to any user ID in the web application and does not store any personally identifiable information. |

| __cfduid | 29 days 23 hours 59 minutes | The cookie is used by cdn services like CloudFare to identify individual clients behind a shared IP address and apply security settings on a per-client basis. It does not correspond to any user ID in the web application and does not store any personally identifiable information. |

| __cfduid | 1 year | The cookie is used by cdn services like CloudFare to identify individual clients behind a shared IP address and apply security settings on a per-client basis. It does not correspond to any user ID in the web application and does not store any personally identifiable information. |

| __cfduid | 29 days 23 hours 59 minutes | The cookie is used by cdn services like CloudFare to identify individual clients behind a shared IP address and apply security settings on a per-client basis. It does not correspond to any user ID in the web application and does not store any personally identifiable information. |

| _ga | 1 year | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _ga | 1 year | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _ga | 1 year | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _ga | 1 year | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gat_UA-326213-2 | 1 year | No description |

| _gat_UA-326213-2 | 1 year | No description |

| _gat_UA-326213-2 | 1 year | No description |

| _gat_UA-326213-2 | 1 year | No description |

| _gid | 1 year | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the wbsite is doing. The data collected including the number visitors, the source where they have come from, and the pages viisted in an anonymous form. |

| _gid | 1 year | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the wbsite is doing. The data collected including the number visitors, the source where they have come from, and the pages viisted in an anonymous form. |

| _gid | 1 year | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the wbsite is doing. The data collected including the number visitors, the source where they have come from, and the pages viisted in an anonymous form. |

| _gid | 1 year | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the wbsite is doing. The data collected including the number visitors, the source where they have come from, and the pages viisted in an anonymous form. |

| attributionCookie | session | No description |

| cookielawinfo-checkbox-analytics | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Analytics" category . |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-non-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Non Necessary". |

| cookielawinfo-checkbox-non-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Non Necessary". |

| cookielawinfo-checkbox-non-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Non Necessary". |

| cookielawinfo-checkbox-non-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Non Necessary". |

| cookielawinfo-checkbox-performance | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category "Performance". |

| cppro-ft | 1 year | No description |

| cppro-ft | 7 years 1 months 12 days 23 hours 59 minutes | No description |

| cppro-ft | 7 years 1 months 12 days 23 hours 59 minutes | No description |

| cppro-ft | 1 year | No description |

| cppro-ft-style | 1 year | No description |

| cppro-ft-style | 1 year | No description |

| cppro-ft-style | session | No description |

| cppro-ft-style | session | No description |

| cppro-ft-style-temp | 23 hours 59 minutes | No description |

| cppro-ft-style-temp | 23 hours 59 minutes | No description |

| cppro-ft-style-temp | 23 hours 59 minutes | No description |

| cppro-ft-style-temp | 1 year | No description |

| i18n | 10 years | No description available. |

| IE-jwt | 62 years 6 months 9 days 9 hours | No description |

| IE-LANG_CODE | 62 years 6 months 9 days 9 hours | No description |

| IE-set_country | 62 years 6 months 9 days 9 hours | No description |

| JSESSIONID | session | The JSESSIONID cookie is used by New Relic to store a session identifier so that New Relic can monitor session counts for an application. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| viewed_cookie_policy | 1 year | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| viewed_cookie_policy | 1 year | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| wmc | 9 years 11 months 30 days 11 hours 59 minutes | No description |

| Cookie | Duration | Description |

|---|---|---|

| __cf_bm | 30 minutes | This cookie, set by Cloudflare, is used to support Cloudflare Bot Management. |

| sp_landing | 1 day | The sp_landing is set by Spotify to implement audio content from Spotify on the website and also registers information on user interaction related to the audio content. |

| sp_t | 1 year | The sp_t cookie is set by Spotify to implement audio content from Spotify on the website and also registers information on user interaction related to the audio content. |

| Cookie | Duration | Description |

|---|---|---|

| _hjAbsoluteSessionInProgress | 1 year | No description |

| _hjAbsoluteSessionInProgress | 1 year | No description |

| _hjAbsoluteSessionInProgress | 1 year | No description |

| _hjAbsoluteSessionInProgress | 1 year | No description |

| _hjFirstSeen | 29 minutes | No description |

| _hjFirstSeen | 29 minutes | No description |

| _hjFirstSeen | 29 minutes | No description |

| _hjFirstSeen | 1 year | No description |

| _hjid | 11 months 29 days 23 hours 59 minutes | This cookie is set by Hotjar. This cookie is set when the customer first lands on a page with the Hotjar script. It is used to persist the random user ID, unique to that site on the browser. This ensures that behavior in subsequent visits to the same site will be attributed to the same user ID. |

| _hjid | 11 months 29 days 23 hours 59 minutes | This cookie is set by Hotjar. This cookie is set when the customer first lands on a page with the Hotjar script. It is used to persist the random user ID, unique to that site on the browser. This ensures that behavior in subsequent visits to the same site will be attributed to the same user ID. |

| _hjid | 1 year | This cookie is set by Hotjar. This cookie is set when the customer first lands on a page with the Hotjar script. It is used to persist the random user ID, unique to that site on the browser. This ensures that behavior in subsequent visits to the same site will be attributed to the same user ID. |

| _hjid | 1 year | This cookie is set by Hotjar. This cookie is set when the customer first lands on a page with the Hotjar script. It is used to persist the random user ID, unique to that site on the browser. This ensures that behavior in subsequent visits to the same site will be attributed to the same user ID. |

| _hjIncludedInPageviewSample | 1 year | No description |

| _hjIncludedInPageviewSample | 1 year | No description |

| _hjIncludedInPageviewSample | 1 year | No description |

| _hjIncludedInPageviewSample | 1 year | No description |

| _hjSession_1776154 | session | No description |

| _hjSessionUser_1776154 | session | No description |

| _hjTLDTest | 1 year | No description |

| _hjTLDTest | 1 year | No description |

| _hjTLDTest | session | No description |

| _hjTLDTest | session | No description |

| _lfa_test_cookie_stored | past | No description |

| Cookie | Duration | Description |

|---|---|---|

| loglevel | never | No description available. |

| prism_90878714 | 1 month | No description |

| redirectFacebook | 2 minutes | No description |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |