Digital Twins: implementing digital twins in industry

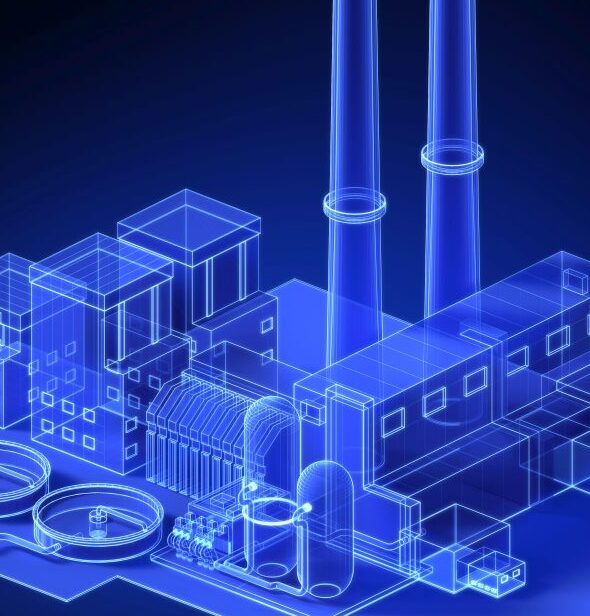

Digital twins are one of the most promising technologies of the moment for many sectors, and industry is one of the most likely to benefit. Digital twins make it possible to simulate how an industrial plant behaves, even before it comes into existence. By simulating changes in production, problems can be avoided before they occur, downtime can be minimised or production can be customised to adapt industry to flexible manufacturing. A consortium including Plain Concepts together with Deuser and TycheTools, and onTech Innovation as coordinator, will develop this project to boost a technology now limited by the entry barriers of digitalisation, the lack of tools to automate data tagging and the difficulty to manage data.

– Project file code: AEI-010500-2022b-47

– Project funding bodies: Spanish Ministry of Industry, Tourism and Trade, AEI Cluster, EU Next Generation Programme and Recovery, Transformation and Resilience Plan.

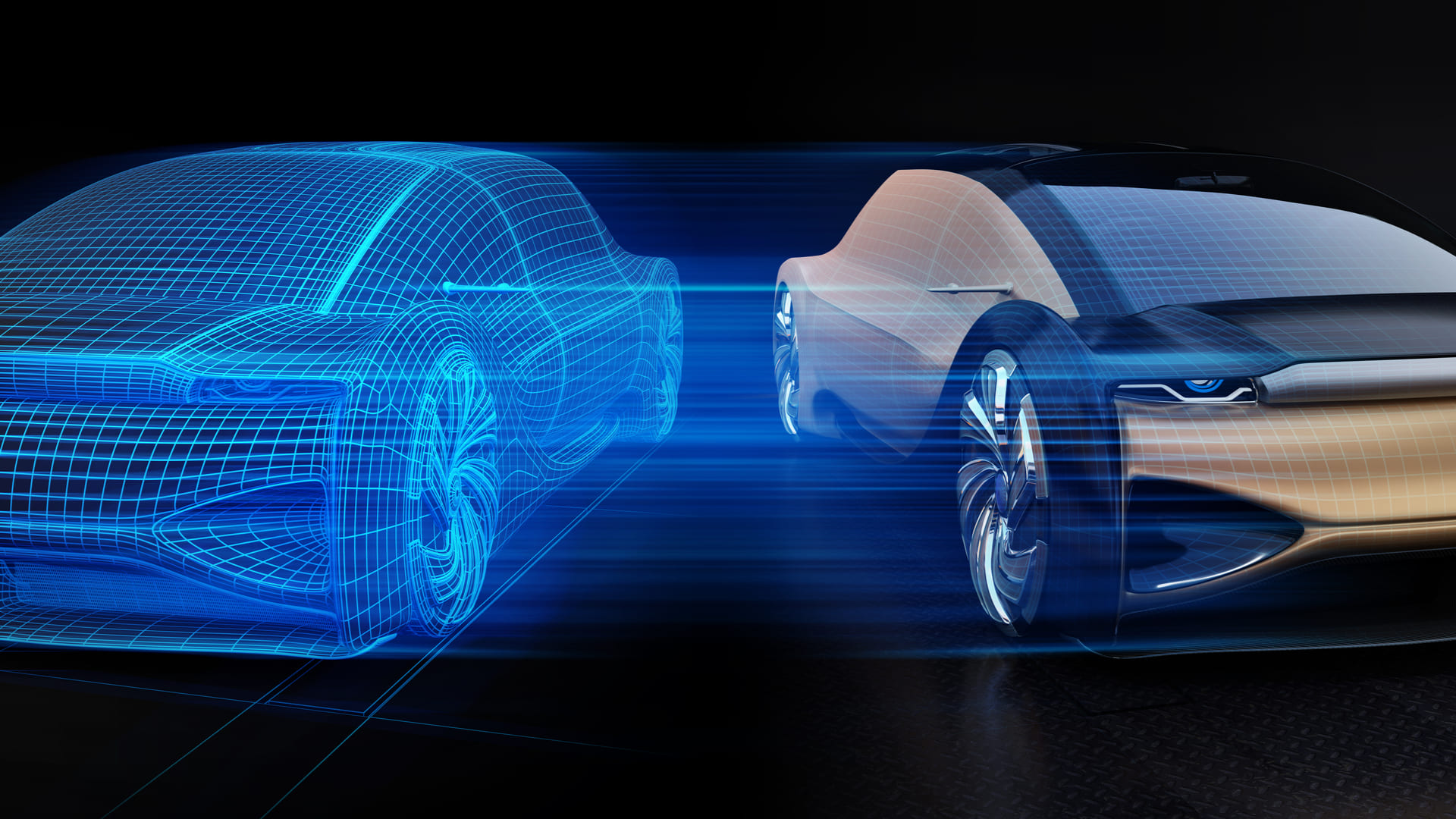

To create a tool to drive the implementation of the very attractive digital twins in the industry. Auto Digital Twins is an ambitious project that, through the generation of 3D models and massive automatic labelling, seeks to promote this technology that makes companies more productive and eliminates the need for physical models.

Thus, the aim of the three phases of the project is to facilitate the labelling of 3D elements (until now very costly) that form part of industrial infrastructures.

The process

Phase 1: Point Cloud to 3D automation. The Spot robot will be used together with the Leica sensor to scan an industrial installation and a point cloud will be obtained as a result. Artificial intelligence algorithms will be implemented on point clouds to recognise complex objects and, once recognised, a 3D model will be obtained.

The solution is based on an AI and Augmented Reality approach.

Phase 2: synthetic data generator. Given the lack of data to recognise objects, a synthetic generator capable of creating massively labelled virtual scenarios will be developed. Artificial intelligence models will be trained with them.

Phase 3: advanced capabilities. In this phase, the aim is for the system to be able to recognise the materials of objects (PVC, aluminium, steel, iron and rubber) based on the detection of textures, as well as their behaviour (for example, the direction and speed of movement of a conveyor belt roller).

Development with Evergine and Point Cloud.

Solution to automate the data collection process.

Results

- Acceleration of digitisation and modernisation of corporate infrastructures.

- Advancement in the new paradigm of Industry 4.0. – Progressive rendered viewer capable of smoothly displaying large point clouds.

- Synthetic data generation.

- Extension of the tool’s capabilities for geometric object reconstruction.

- Real-time and historical analysis

We are ready for new challenges